Our Services

Rejuvenation

Rewinding

Manufacture of special parts for off-line engines

Machining

Encoder installation

Static tests

Balancing

Change in a constructive way

Resale of engines, parts and pieces

Training and consultancy

Gearbox maintenance

EX engine maintenance

Global confidence

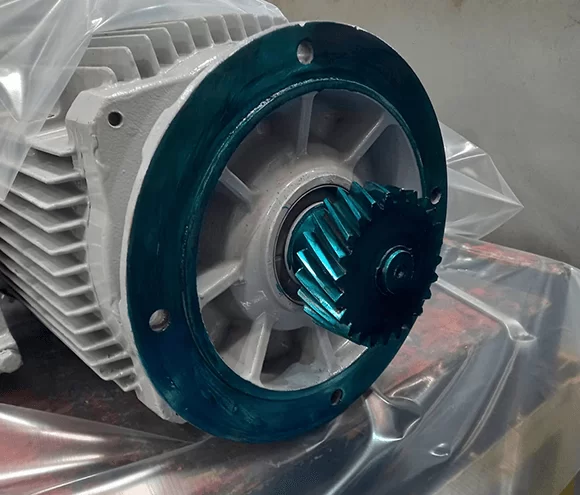

Quality inspection.

Before it goes back into operation, it goes through a rigorous validation process, where precision and quality are tested down to the last detail.

Proven efficiency

Success stories.

We reduced the excessive vibration of a motor by relocating and optimizing the junction box, which was previously large and distant. After a technical study with the engineering team, we repositioned the box close to the motor, with an ideal size. O result? Less downtime, more productivity and a longer service life in the customer's plant.

Our difference

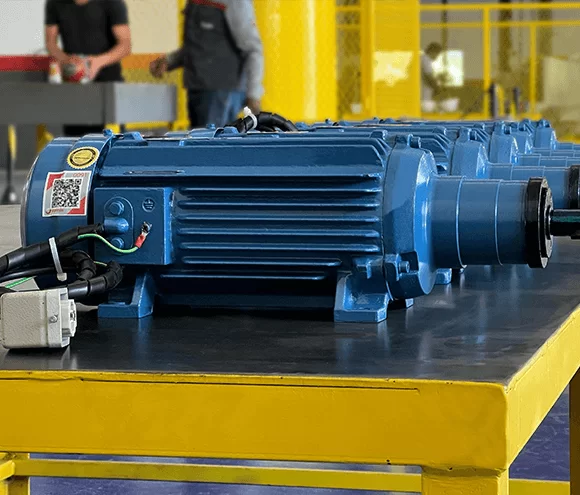

Fast traceability.

The tags on the equipment guarantee total traceability and instant access to the complete service history. Through QR Codes customized to the client's needs, it is possible to consult the initial and final reports of each intervention in seconds, with practicality, security and total transparency.

Our difference

Heat shrink packaging.

All the engines Kairós services are packaged using heat-shrink technology, guaranteeing total protection against humidity, dust, impacts and climatic variations. This protection preserves the integrity of the equipment during transportation and storage, ensuring that each engine reaches the customer with the same standard of quality as when it left our workshop.

Solutions gallery